Huawei has introduced open-road tolling (ORT) technology to facilitate the removal of expressway toll gates at provincial borders, thus greatly reducing traffic congestion and transportation costs, and making road transport more convenient.

ORT is a milestone for transportation, driving digital transformation and evolution towards smart highways. Facing a tight schedule and significant workload, the removal project needs to overcome five technical challenges.

Challenge One: Implementing management and control to prevent toll losses

Huawei leverages cloud computing, Big Data, Internet of Things (IoT) and Artificial Intelligence (AI) technologies to provide double assurance for the management and control of toll evasion and losses.

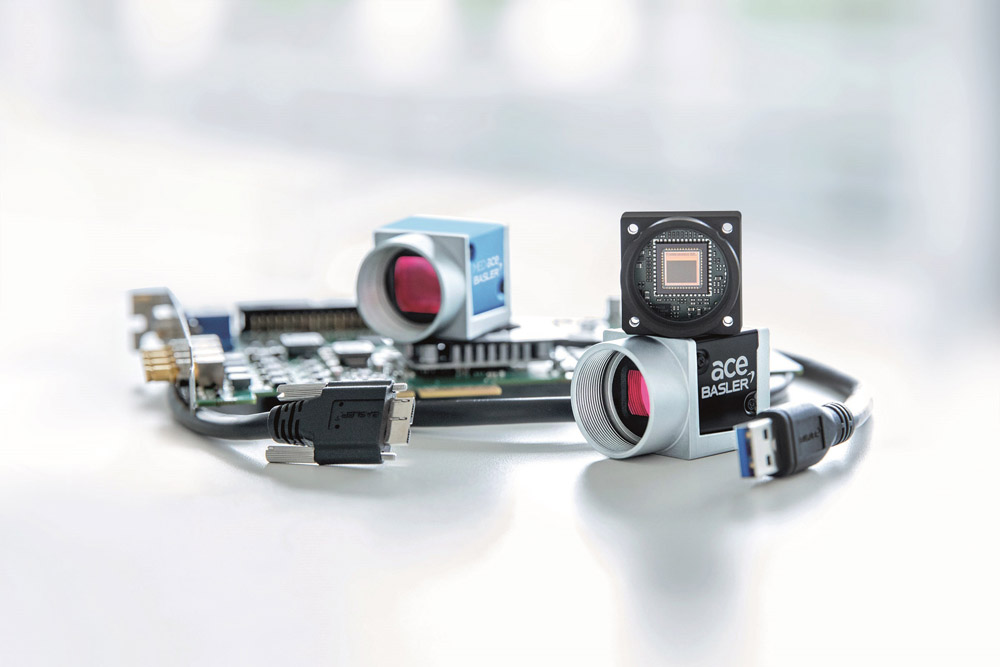

Level-1 assurance: Huawei's intelligent licence plate recognition cameras support online algorithm upgrade to continuously improve recognition accuracy, and the cameras feature Huawei's proprietary chips with high computing power.

As new licence plate recognition algorithms are developed and loaded, the cameras achieve a higher recognition rate with better accuracy, maximising return on investment (ROI). The cameras support the software-defined feature and can automatically identify all weather conditions - including heavy rain, snow, and fog - and adjust imaging parameters accordingly to ensure clear snapshots of each licence plate and vehicle.

Huawei's intelligent licence plate recognition cameras with global shutter technology are designed specifically for highways. This technology enables a licence plate recognition rate of over 99% when vehicles are driving at a speed of 220km/h.

Level-2 assurance: Based on Huawei's digital platform capabilities, build a real-time, accurate toll collection and inspection Big Data cloud platform featuring cloud-edge synergy between the provincial center and electronic toll collection (ETC) gantries.

Use edge computing on the ETC gantry system to implement real-time analysis and matching between recognised licence plates and vehicle information detected by road side units (RSUs). Report exceptions to the provincial centre and synchronise the information to relevant toll gates for timely management and control.

Challenge Two: Ensuring the stability, reliability and security of new ETC gantry systems

In terms of stability and reliability, make sure that toll collection services can run properly for a long time without suffering core data losses, including toll collection data and licence plate images.

Over two million Huawei FusionCube cabinets have been deployed worldwide by more than 310 carriers, governments, and enterprises. The cabinets withstand myriad hostile environments, such as those with temperatures below –40°C and over +50℃, and can operate 24/7 without disruption.

The nodes of the integrated smart site perform intelligent edge computing, carrying toll collection and billing services. The nodes are deployed in redundancy mode and support hot standby to enable seamless service switchover and ensure toll collection continuity upon a single point of failure (SPOF).

The site uses SSD all-flash disk arrays to bear and store core data. The arrays are equipped with redundant controllers to prevent SPOF, and use redundant array of independent disks (RAID) technology to quickly restore data in the case of a disk fault. It takes less than 30 minutes to restore one terabyte of data.

Huawei leverages its technical advantages in network and security domains and uses proprietary chips to safeguard security. Security protection measures, such as IP address filtering and network access authentication, prevent hackers from accessing or hindering the toll collection system. Collaboration between network and security is implemented to block attack sources when necessary.

Huawei-proprietary chips are deployed in sensing, computing, storage and communications devices of Huawei ETC gantry systems, toll gates, road section centres and the provincial centre, ensuring chip-level security and controllability of the entire system.

Challenge Three: Achieving unified O&M management

Huawei provides an integrated operations management platform for numerous ETC gantry systems. The platform intelligently manages key functional modules, such as FusionCube cabinets at integrated smart sites of ETC gantries, power supply systems, power back-up systems, cybersecurity modules, edge computing modules and data storage modules on a unified GIS map. This helps comprehensively operate and manage ORT.

Challenge Four: Tight schedule and challenging tasks, requiring quick, high quality project construction

Measure twice, cut once. The seemingly simple ETC gantry system needs to be designed and verified in advance in that it involves multiple procedures, including engineering commissioning and functional module collaboration. The Huawei ETC gantry system adopts an integrated design to prevent heterogeneity, interoperability, and compatibility issues between software and hardware modules.

In particular, the collaboration between heterogeneous systems from various brands and suppliers is avoided, greatly reducing integrated commissioning costs at the construction site. Huawei's integrated smart sites have undergone pre-testing and verification at Huawei's Suzhou OpenLab and Beijing R&D centre.

In addition, the sites have been tested on highways in multiple cities, to confirm they meet technical specifications and requirements of the ETC gantry system.

Device supply, construction mode and resource support need to be fully prepared as well. Huawei has already established one competence centre at its HQ, two remote delivery centres, and 31 provincial delivery centres, with 150+ project management experts and 4,000+ delivery engineers. These comprehensive resources support the removal of all expressway toll gates at provincial borders.

Challenge Five: Enabling smooth technology and investment upgrade to maximise ROI and evolve towards smart highways

Huge investment has been put into ETC gantry systems, which are critical infrastructure for future operating services of toll roads. Applying cutting-edge technologies to facilitate smooth upgrade to smart highways and maximise ROI is paramount.

Huawei's integrated smart site of ETC gantry supports collaboration and scalability, and is compatible with multiple technologies, such as 5G. The site contains Huawei-proprietary AI chips and uses intelligent edge computing to enable licence plate recognition image deduplication, secondary recognition of images, vehicle model recognition, and HD video analysis, promoting more accurate toll collection and inspection. Simultaneously, the site provides technical support for 5G technology and Vehicle to Everything (V2X) on smart highways, maximising hardware ROI.

Huawei's integrated smart site of ETC gantry supports collaboration and scalability, and is compatible with multiple technologies, such as 5G. The site contains Huawei-proprietary AI chips and uses intelligent edge computing to enable licence plate recognition image deduplication, secondary recognition of images, vehicle model recognition, and HD video analysis, promoting more accurate toll collection and inspection. Simultaneously, the site provides technical support for 5G technology and Vehicle to Everything (V2X) on smart highways, maximising hardware ROI.

Huawei is a leading global information and communications technology (ICT) solutions provider and is committed to innovating in the transportation industry. We work with partners to build an open, cooperative industry ecosystem and promote digital transformation to create a better-connected world.

Please click here for more information on the above-mentioned technology.

Content produced in association with Huawei