High profile fatal fires following accidents in the Mont Blanc, Tauern and Gotthard tunnels prompted the 2004 European Union Directive 2004/54 on road tunnel safety. This meant all EU member states would have to meet new standards of safety in road tunnels by 30 April 2014. The Directive applied to all tunnels over 500m long on the Trans European Road Network (

A number of EU member states are known to have met the Directive’s deadline. Others have been able to take advantage of an extension allowed to countries with more than the European average of 500m tunnels per km of TERN. These countries have until April 2019 to comply with the EU Directive.

Italy is understood to be one of the EU states that can fall back on the deadline concession. The country has around one half of all of the long tunnels on TERN roads, and so potentially a heavy burden of safety upgrades to carry out.

“The trouble is, Italy does not have the billions of euros needed,” says a source close to the EU’s road tunnel safety programme. “It has the extension to 2019, but no chance of meeting it, so Italian authorities have introduced a system of risk assessment analysis as an attempt at showing compliance.” The same source continues: “Southern Europe has a lot of tunnels. Spain also has difficulty due to the huge sums involved, so has back tracked on the deadline, but Norway, which is not in the EU, is religiously adopting the requirements of the Directive, spending around three to four billion euros in the process.”

Status report

According to the European Commission, nine EU member states are known to have fulfilled the requirements of the tunnels Directive: Cyprus, the Czech Republic, Finland, Hungary, Ireland, the Netherlands, Portugal, Slovakia and Sweden. Five states currently do not have any tunnels qualifying under the Directive (Estonia, Latvia, Lithuania and Malta). Seven have taken advantage of the deadline extension – Austria, Croatia, Greece, Italy, Luxembourg, Slovenia and Spain.That leaves a list of seven EU members that, according to an EC spokesperson, have yet to inform the commission of their compliance. This list includes Germany, France and the UK, as well as Belgium, Bulgaria, Denmark and Poland.

The engineering group most closely associated with European tunnel safety – cited as the source of expertise behind much of the EU Directive – is the World Road Association’s (WRA, or

Marc Tesson is an expert advisor in international networks and research for France’s tunnels study centre CETU (Centre d’Etudes des Tunnels). Tesson is also the member of the WRA tunnels committee currently providing liaison with the EC’s tunnel safety working group.

“The EC launched a new project last year aimed at getting a new update on all member states’ progress. An Italian consultant was commissioned for the task, and as far as we know, that team is currently finalising its report,” Tesson says.

With regard to the state of play in his own country, France has 32 tunnels over 500m long on TERN roads. Safety upgrades have been completed on 29 of these, with the remaining three due to finish soon, Tesson says.

France has about 200 tunnels that needed refurbishment to meet new French regulations covering all road tunnels over 300m in length. A programme of retrofitting safety upgrades to all of these tunnels – including seven owned bi-nationally – has now been completed, at a large cost. Just the 86 tunnels owned by the French state have been upgraded at a cost of 2.7 billion euros.

“We have faced a very big challenge over the past 10 years, helping all of France’s tunnel owners and operators meet the new safety requirements,” Tesson says.

France has benefitted from having the CETU, an 85-strong tunnels research and development group attached as a department of the French government.

“We at CETU have been in charge of setting regulations and providing engineering guidance regarding tunnels, including that relating to safety of operations,” Tesson says. CETU is the only Government organisation of its type in Europe. It would appear that a number of other countries would be happy to have such a group of experts able to work directly with Government and tunnel owners.

Holistic approach

The strategy adopted in France, as recommended by the EU Directive, has focused on encouraging tunnel operators to adopt a systemic approach, assessing safety levels holistically, Tesson says. This has been supported with a series of guidance documents on methods for upgrading and operating to higher levels of safety.“It has been very important to get all to buy into and adopt this ethos of demonstrating an overall safety level for each and every tunnel based on the particular circumstances, of traffic levels, vehicle types, tunnel geometry, design and emergency procedures,” says Tesson.

“Coordination between all interested parties has been vital for this. We haven’t wanted to prescribe the sort of equipment or particular measures operators should use, rather encourage them to adopt this global system approach.”

Very similar approaches are evident elsewhere in Europe, following risk and safety level assessments as recommended by the EC Directive, which sets out a range of other safety obligations for tunnel operators.

Appointment of a tunnel manager and safety officer are mandatory, with responsibilities such as maintaining standards of staff training and equipment maintenance. Arranging regular safety inspections by an independent entity are also obligatory for tunnel authorities.

Best practice

To a certain level, the Directive is prescriptive on technology. Automatic incident detection is a requirement for tunnels monitored from control centres, which themselves are mandatory for any tunnel over 3km long and carrying daily traffic flow of more than 2,000 vehicles per lane.Longitudinal ventilation systems are no longer allowed in single bore, uni-directional tunnels, unless in special circumstances proven by risk analysis, or if other special measures are carried out. Frequently this means installation of transverse or semi-transverse ventilation where smoke and gasses are drawn upwards before being vented from tunnel portals or intermediate vents.

WRA committee member Fathi Tarada is managing director of Mosen, a specialist in tunnel safety systems. “Across Europe, many billions have been spent on upgrades. A lot of the cross-Alpine tunnels have been dualled and given new evacuation routes as well. It could be argued that many needed to be dualled anyway to increase traffic capacity, but it seems it has all been done quicker because of the need to meet the Directive,” Tarada says.

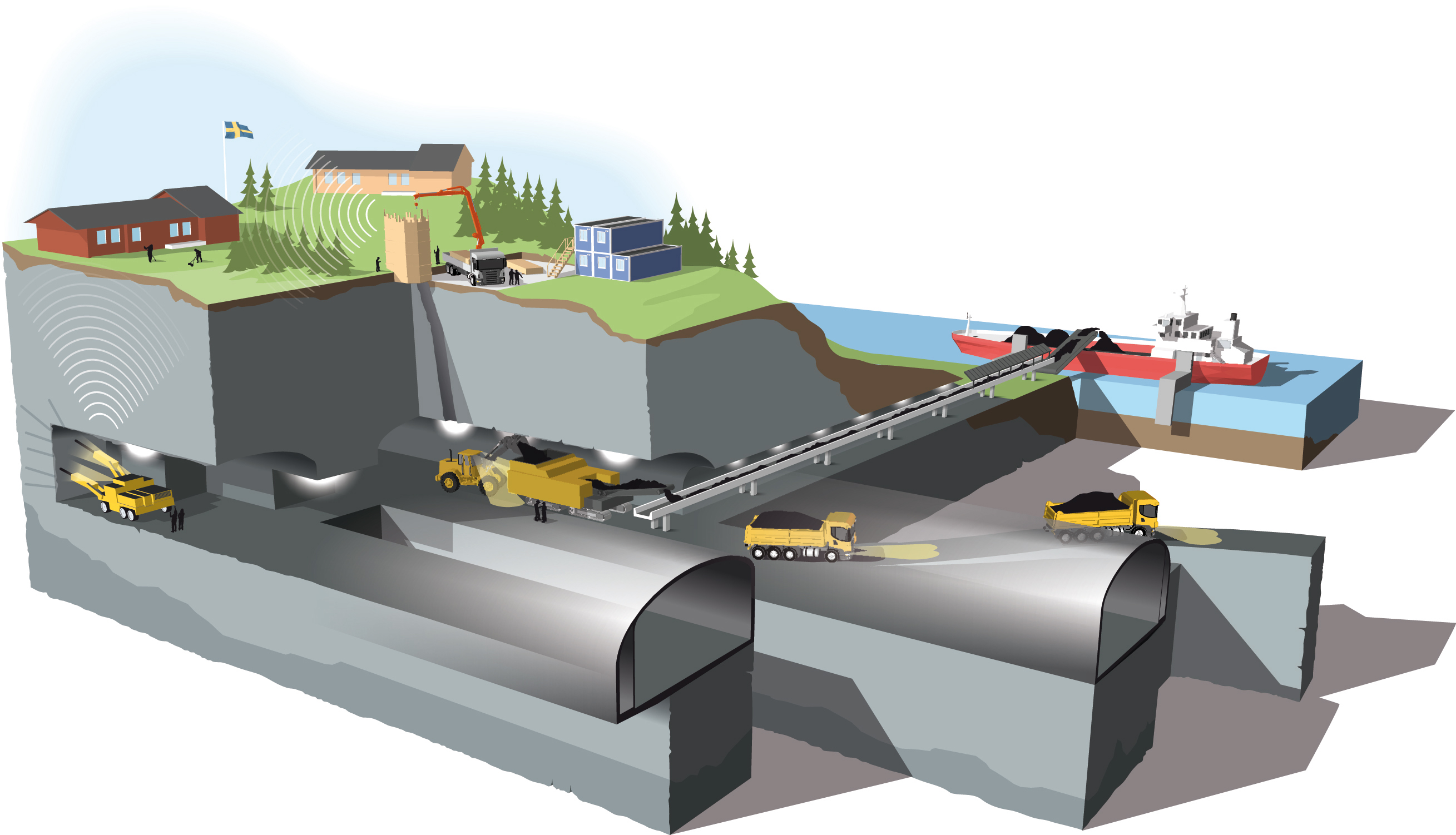

In some cases, new secondary tunnel bores have been driven to provide emergency escape routes instead of providing further traffic capacity. This is being done in the case of the Gotthard Tunnel. A new secondary tunnel is to be bored, but this will serve as a safety evacuation route only due to political restrictions on expansion of roads through the Swiss Alpine region.

“Best practice is evolving and divergent in some ways, with different views on it, but most countries are specifying various forms of fire suppression technology now, which wasn’t the case five years ago,” Tarada says.

“A quantitive risk assessment carried out for the dualling and upgrade of the Tyne Tunnel in Newcastle showed these tunnels should have a fire suppression system, which has now become a defacto standard in Europe.”

The 14km long Arlberg Tunnel in Austria is now getting fire suppression fitted because it lessens the risk of fire spread.

“Combined with a good modern ventilation system, incident detection and response plan, risk can be mitigated sufficiently to negate the need for a second tunnel bore,” he concludes.

Improvements in Wales

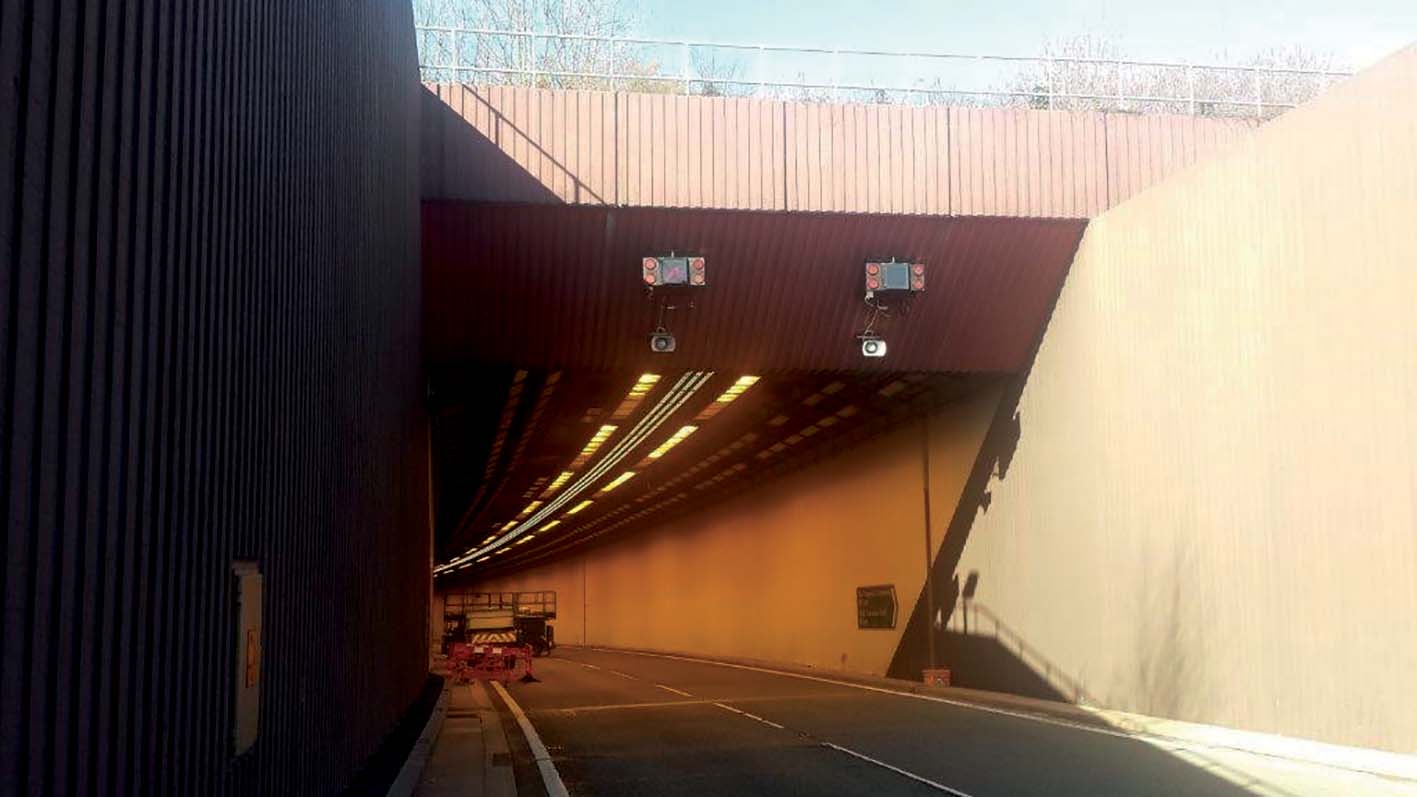

Three road tunnels on the route of the A55 in North Wales have now been refurbished to meet the UK’s road tunnel safety regulations, drawn up in accordance with the EC Directive 2004/54.

Both the Pen-y-Clip Westbound Tunnel, at 930m long, and the Penmaenbach Westbound, 658m long, carry uni-directional single carriageway in rock tunnel bores (eastbound traffic uses much shorter tunnels or headland roads on sea walls along the A55 coast road). The Conwy Tunnel is an immersed tube structure 1060m long carrying dual bi-directional carriageway under the Conwy Estuary.

According to the Welsh Assembly Government, the full scope of works carried out was established via a process of risk assessment and gap analysis. All three tunnels now have automatic incident detection and public address systems, plus new way finding signs, evacuation lighting and passive fire protection for electrical and communication systems.

“In addition to this work, further improvements have been procured in accordance with relevant UK standards,” a Welsh government spokesman says. These additional upgrades include new LED lighting, heat detection systems, ventilation and pollution and visibility sensors.